Smart electronics manufacturing

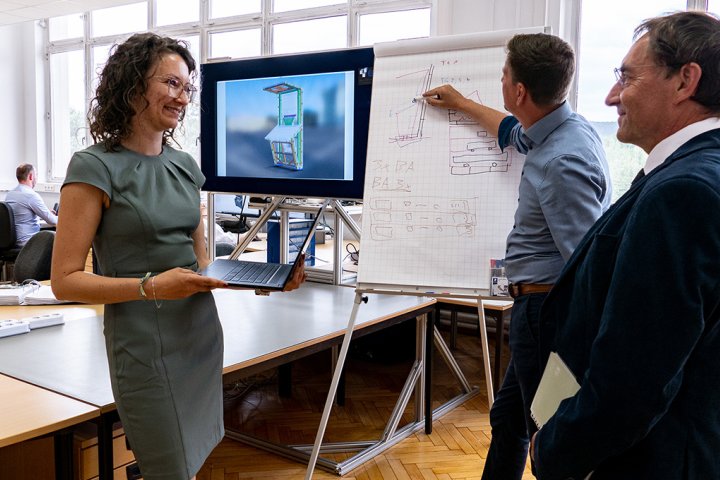

At EPSa, we unite product development and manufacturing under one roof, ensuring a seamless path from concept to completion.

From prototypes to large series, manufacturing at EPSa combines modern equipment, experienced teams, and a strong focus on quality. As a full-service DMS partner, we manage the entire process, from prototyping and assembly to testing and final delivery, ensuring every product is built to the highest standards.

End-to-end production

Manufacturing is more than PCB assembly. Our services cover electronic, mechanical, and mechatronic integration, supported by advanced testing and documentation.

Whether it’s individual modules or complete devices, every step is aligned with your requirements and optimized for efficiency and scalability.

Our competencies:

- Rapid prototyping: from first samples to pre-series

- Surface-mount technology (SMT): high-precision placement and soldering

- Depaneling: advanced separation, such as milling

- Through-hole technology (THT): manual placement and soldering

- In-circuit and functional testing: validating performance and reliability

- X-ray analyzing & Examining: inspection of solder joints and hidden structures

- Cable assembly: tailored wiring and harnesses

- Mechatronic assembly: integration of electronic and mechanical components

- Cleanroom production: for sensitive applications

- Protective coating: protection against moisture, dust, and chemicals

- Box building: complete devices and systems

- Traceability: full tracking of materials, processes, and test results.