Rapid prototyping

Rapid prototyping at EPSa goes far beyond conventional additive manufacturing. With advanced SLS and SLM solutions, we turn even complex or unconventional ideas into reality. Quickly, precisely, and cost-effectively.

From material selection to subassembly integration, our prototyping capabilities provide near-limitless freedom in development and design.

Technical capabilities

Prototypes and small series are produced directly from supplied 3D data, eliminating the need for tooling.

This not only accelerates manufacturing but also reduces costs and minimizes risk. Functional testing and detailed documentation are integrated into the process to validate every design step.

Key advantages:

- Fast production from digital 3D data

- Tool-free manufacturing for cost savings

- Reduced component count in assemblies

- Lower development risk through early validation

- Project-specific material selection

- Integrated validation, testing, and documentation.

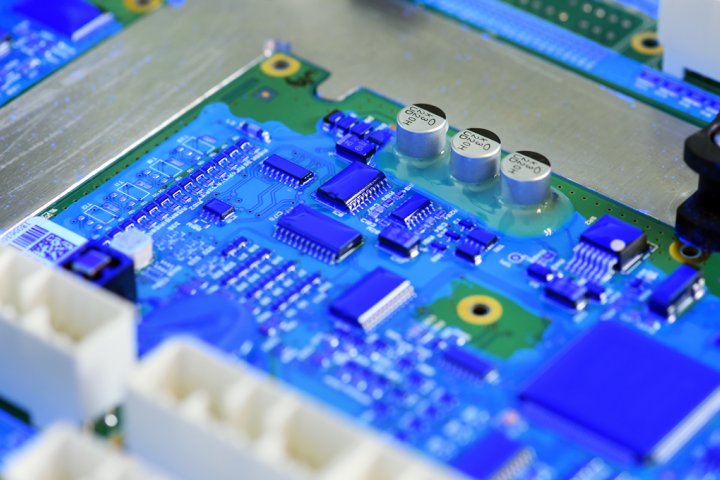

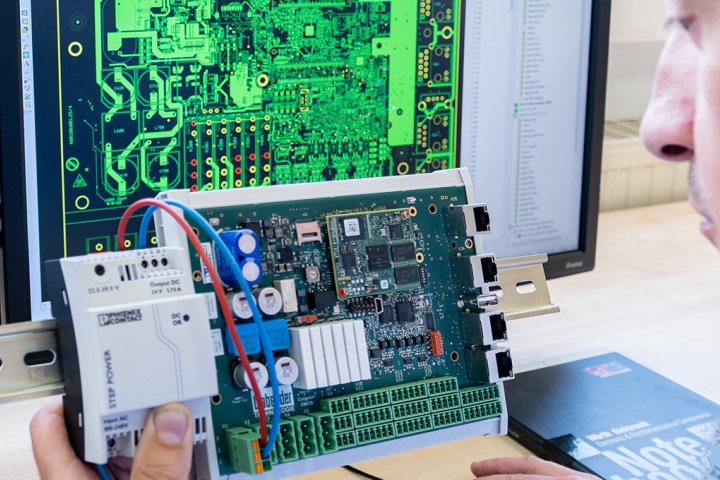

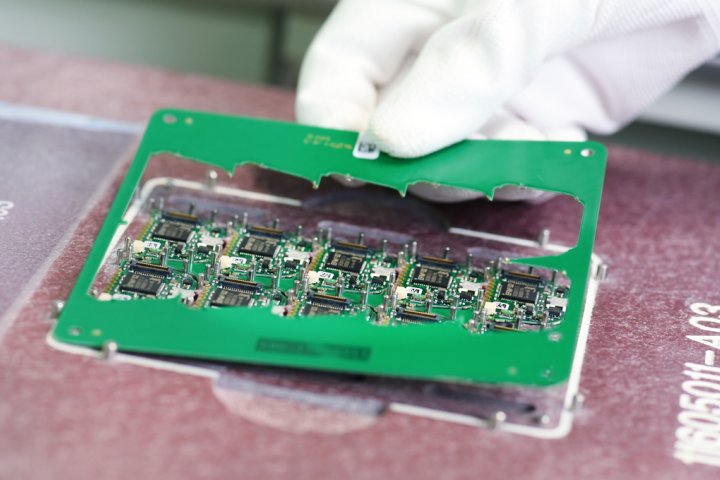

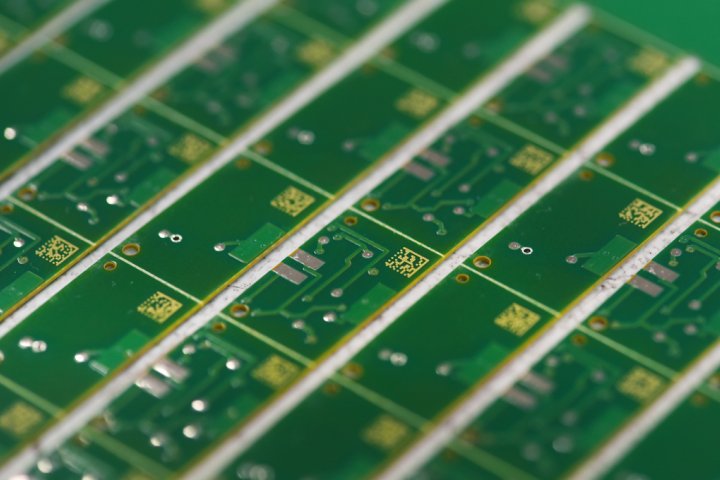

With our Fritsch placeALL 620L placement machine, we produce PCB prototypes in series quality, including fine-pitch components, within just one day. The wide component spectrum ranges from 01005 chips and BGAs to flip chips and connectors, ensuring full flexibility for demanding designs.

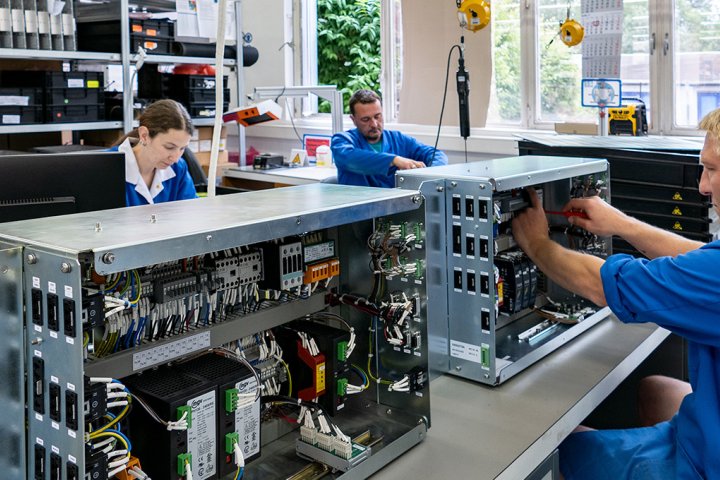

Sampling & Small series production

As a full-service DMS provider, we handle the entire workflow for electronics sampling and pre-series, from hardware and software integration to complete device assembly. Whether a 1:1 prototype or a small production run, we deliver results in series quality to prepare your product for industrial scale.