Protective coating

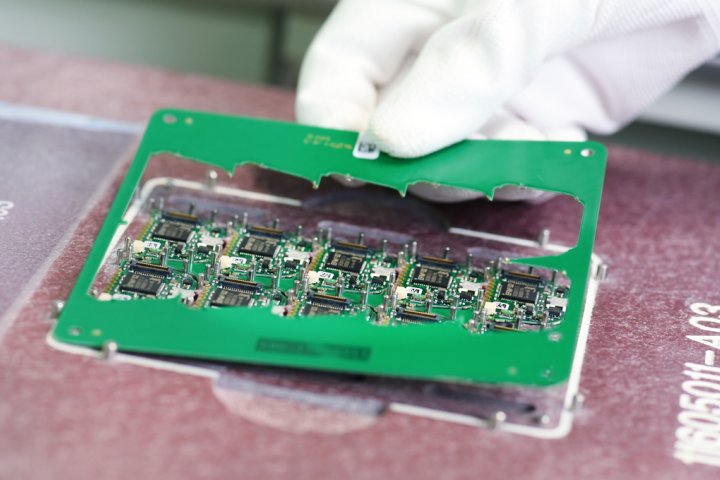

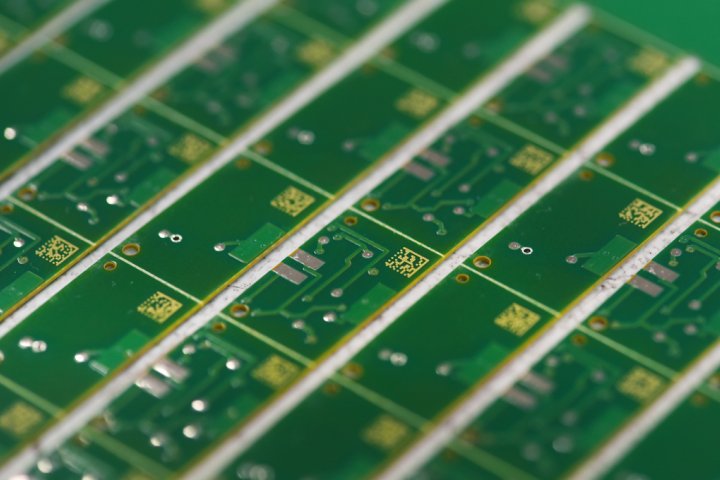

Electronic assemblies must perform reliably for many years, even when exposed to moisture, dust, vibrations, electrical interference, or radiation.

At EPSa, we apply protective coatings and encapsulation processes that safeguard sensitive components and ensure lasting functionality, even in the toughest environments such as automotive, aerospace, or outdoor applications.

Coating and potting technologies

We rely on proven high-quality technologies, including coatings developed by Peters, the global specialist in conformal lacquers.

Depending on application requirements, assemblies are protected through selective or complete coating, nanocoating, or potting with advanced resins. Each process is tailored to deliver maximum reliability while maintaining efficient and cost-effective production.

Capabilities include:

- Surface preparation: pickling degreaser, indium bath, direct metallisation, zinc-nickel and copper alloy baths

- Component cleaning: ultrasonic cleaning with up to 7 programs

- Conformal coating: spray painting with protective lacquers and resins, nanocoating with Certonal

- Potting: casting with silicone, polyurethane, or epoxy resins

- Finishing: screen printing and pad printing for identification and labelling.