Through-hole technology

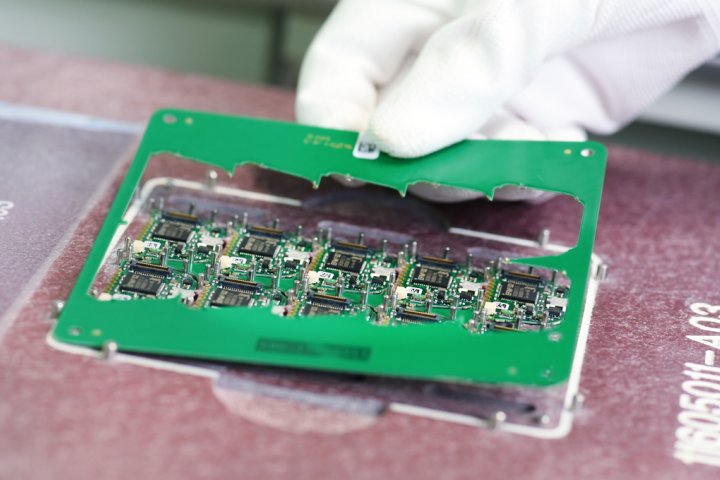

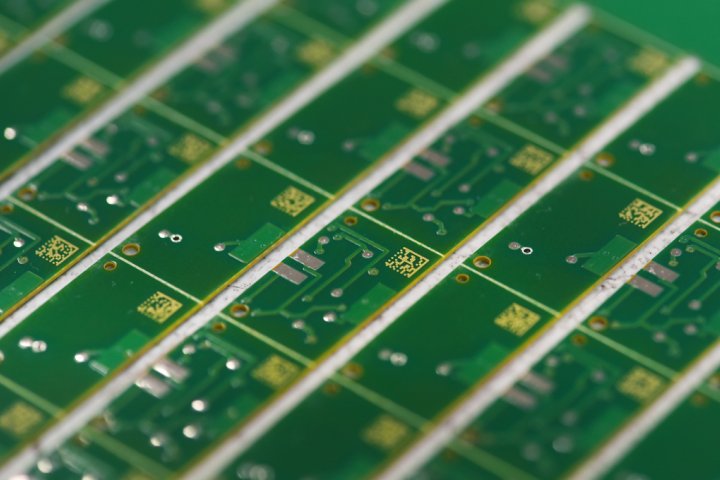

Through-hole technology remains essential for components that require high mechanical strength or special placement, especially in power electronics, connectors, or assemblies exposed to mechanical stress.

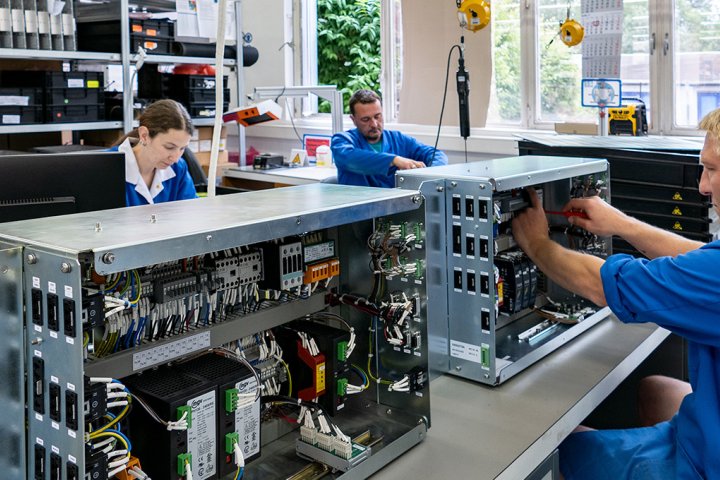

At EPSa, THT assembly is performed both manually and with automated soldering systems, ensuring flexibility for prototypes, small series, and large-scale production.

Manual expertise, automated precision

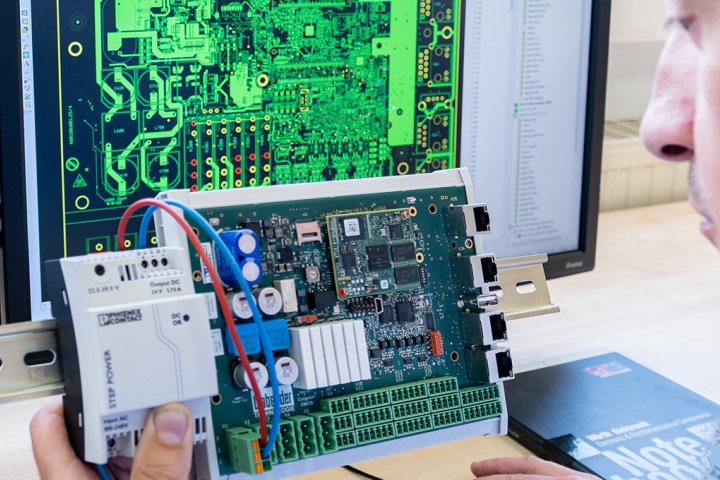

Special components and prototypes are assembled by experienced employees, guaranteeing precision and consistency even in complex designs.

For larger volumes, we combine this expertise with selective and wave soldering systems, achieving repeatable, void-free results that meet the strictest quality standards.

Advanced soldering technologies

- Selective soldering: for targeted, automated solder joints with high reproducibility.

- Wave soldering: for efficient processing of high pin-count assemblies.

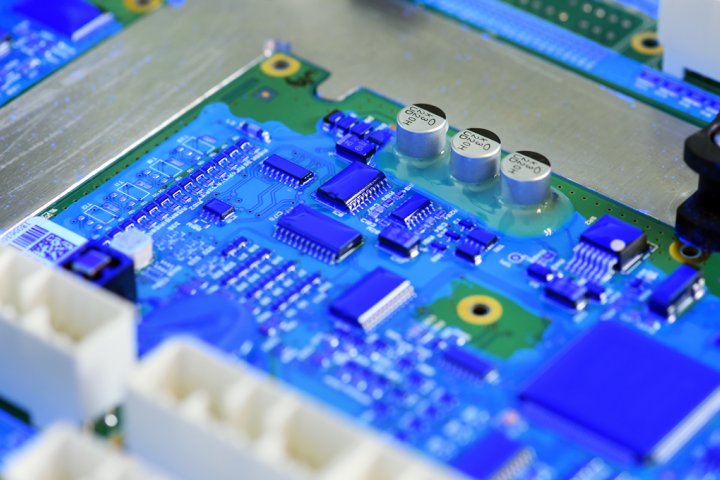

- Vacuum vapour phase soldering: enabling void-free results even in demanding sectors

- Manual soldering: for prototypes, small series, and special components.

Both lead-free and leaded soldering are possible, depending on compliance and application requirements. Integrated inspections ensure that every connection meets our zero-defect strategy.