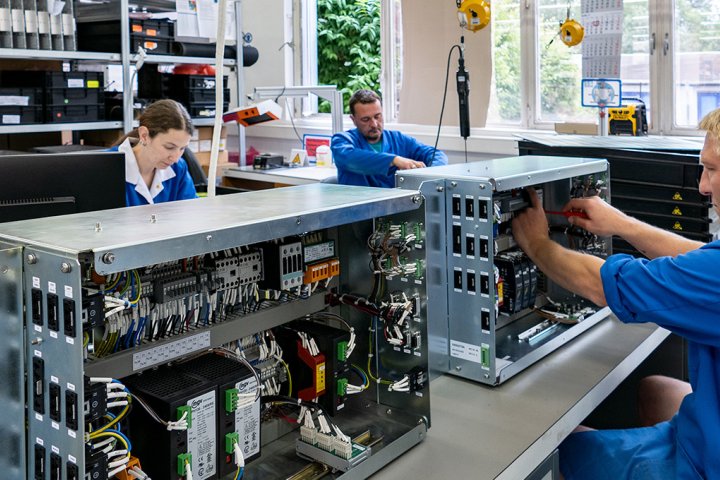

Mechatronic assembly

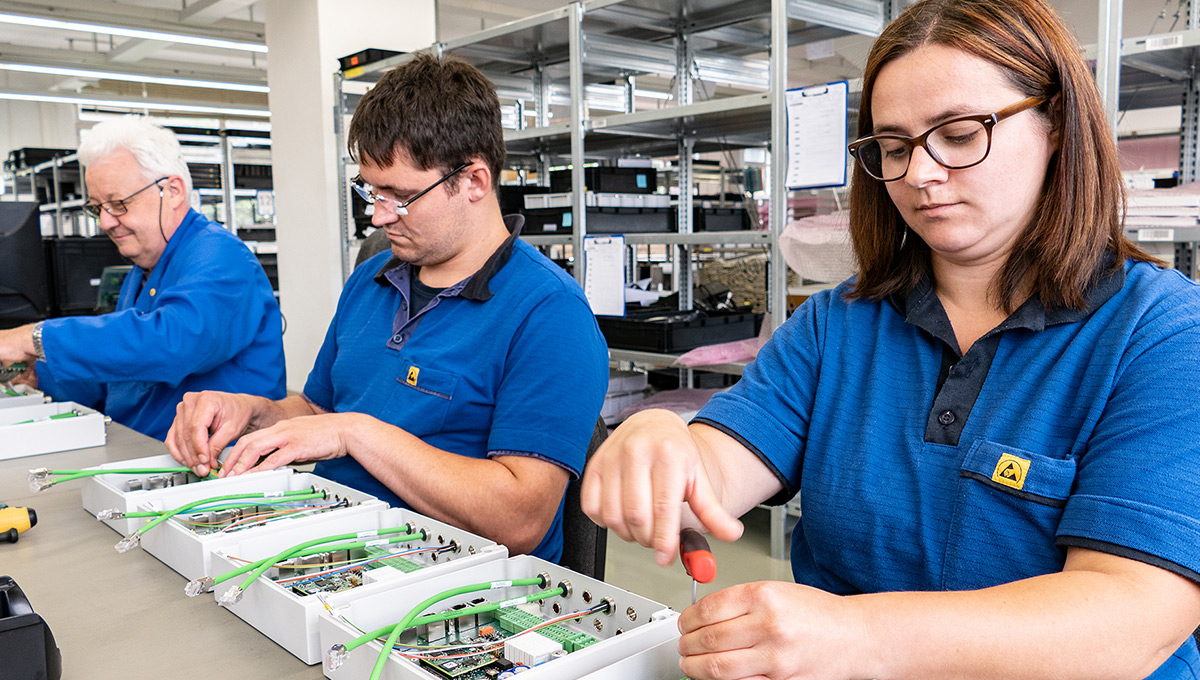

Mechatronic assemblies require precise coordination among production, electronics, and software.

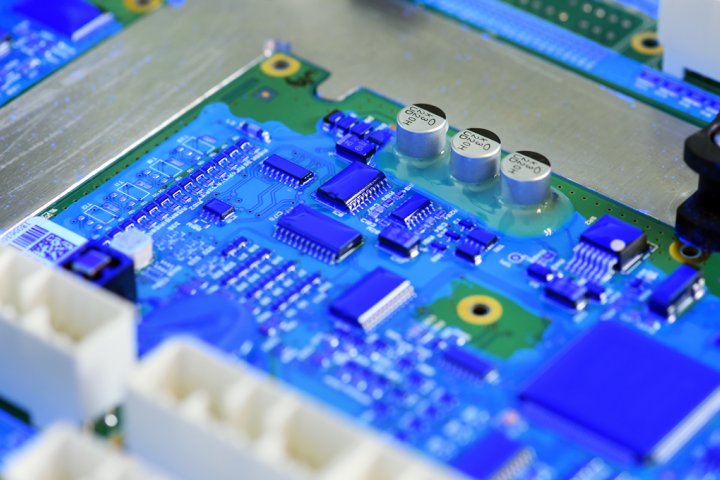

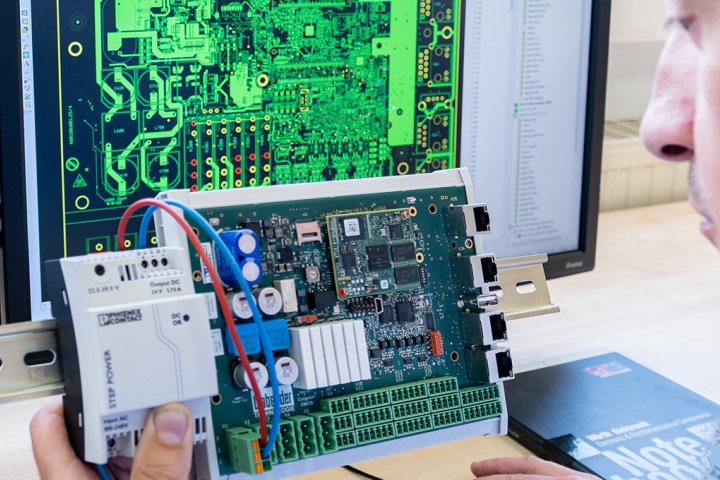

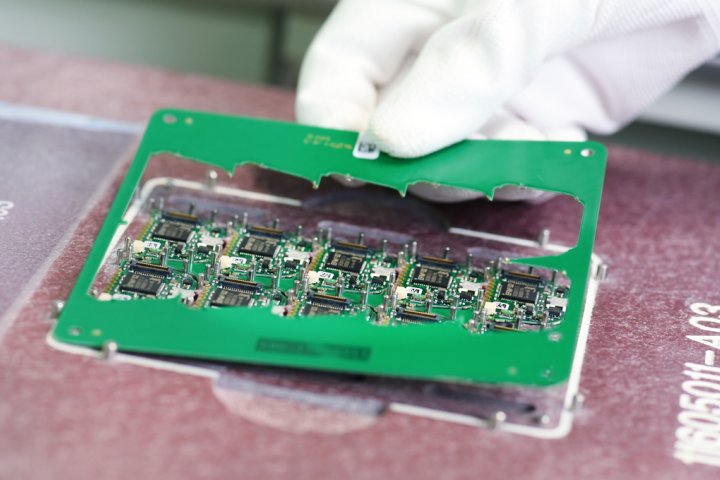

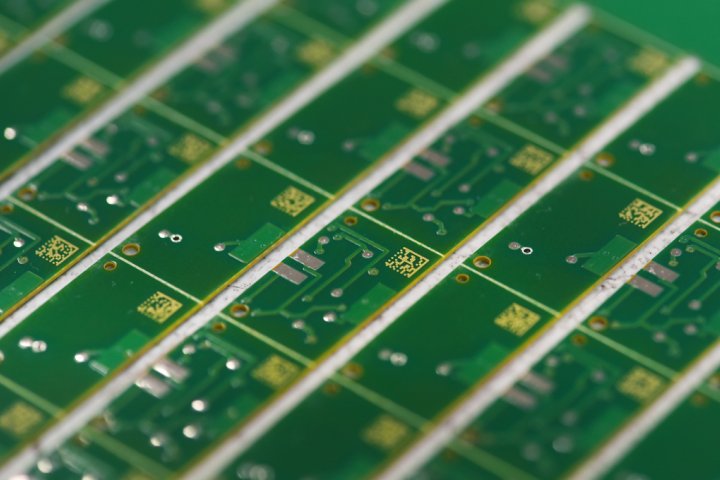

EPSa unites CNC-based machining, SMT/THT PCB assembly, cable harnessing, and embedded software/firmware to deliver electromechanical modules, devices, and complex functional systems, from one-off builds to series production.

Ensuring manufacturability

Precision starts at specification and continues through release. Material selection, data checks, and DFM/DFT ensure manufacturability; careful cleaning, final inspection, and documentation secure consistent performance. When required, assembly and testing take place in clean room environments for sensitive applications.

Key capabilities include:

- Conventional & CNC machining: enclosure and mechanism integration

- PCB assembly (SMT/THT): sample builds and rapid prototypes

- Full mechatronic integration: including cable assembly

- New development & redesign: data check and production optimization

- Functional, electrical, and mechanical testing: commissioning

- Processing of customer-supplied materials: including special sourcing, discontinued parts

- Production: from quantity 1 to series, with documented release.

Certified to DIN EN ISO 9001 and DIN EN ISO 13485, processes ensure traceability and reliability from first article to series. The result: precise, scalable mechatronic systems tailored to your requirements.