Surface-mount technology

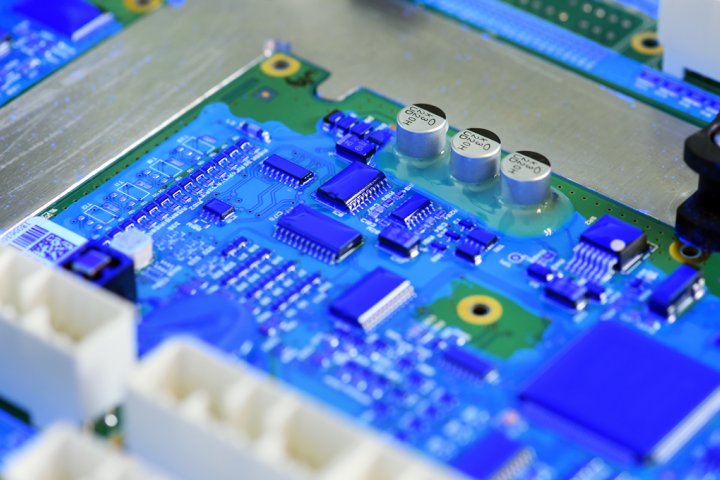

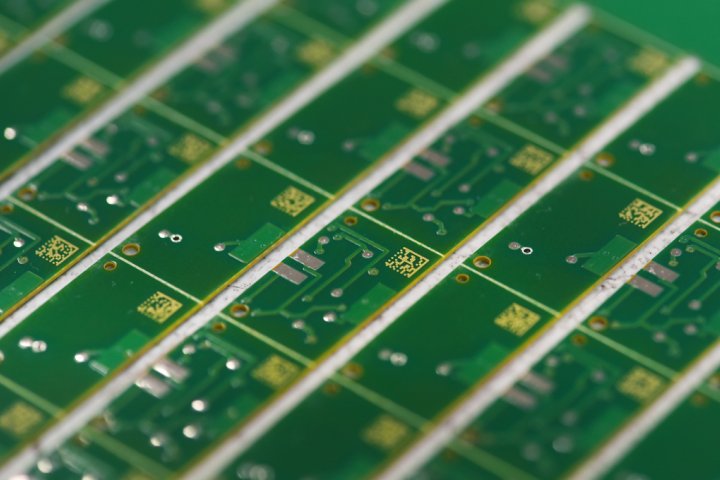

Surface-mount technology is at the core of modern electronics manufacturing.

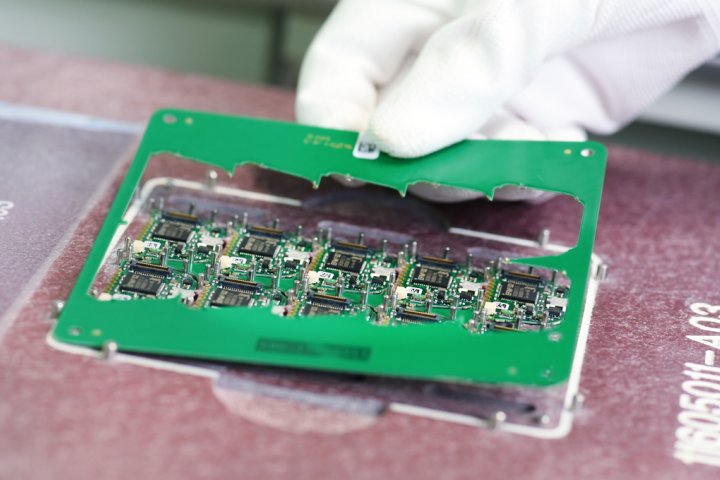

At EPSa, PCBs are assembled on three fully automated Siplace SMD lines, capable of handling the entire component spectrum — from standard resistors and capacitors to microcontrollers, BGAs, and fine-pitch devices. The result: high flexibility, short throughput times, and reliable capacity, even for large-scale orders.

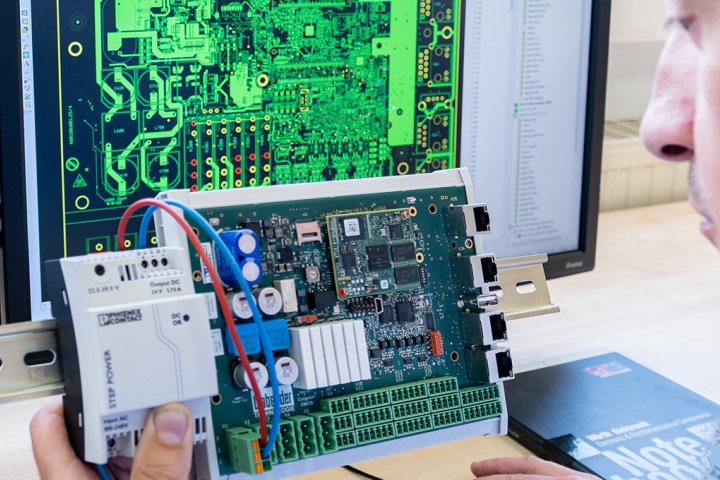

Real-time process control

All SMT lines are networked and integrated into our ERP system, enabling real-time order tracking and synchronized implementation of changes across every stage of production.

This guarantees transparency and ensures that design or process modifications are applied consistently and without delay.

Advanced soldering technologies

Reliable soldering is essential for both performance and product lifetime. We combine multiple soldering techniques to ensure optimal results for every application:

- Reflow soldering: modern 12-zone system with nitrogen supply to ensure consistent quality.

- Vacuum vapour phase soldering: enabling void-free solder joints for highly sensitive applications.

- Options for both lead-free and leaded soldering: depending on requirements and compliance needs.

- Integrated AOI (Automatic Optical Inspection): after soldering to verify quality at the highest level.

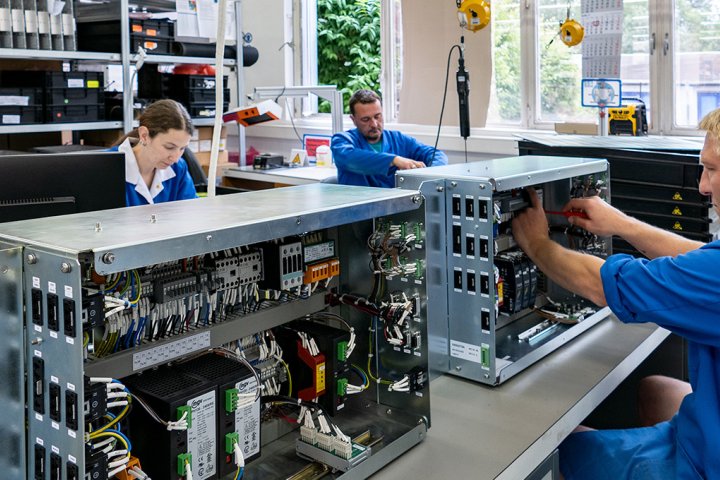

Process reliability built in

Whether prototypes or high-volume series, SMT at EPSa is designed for maximum process stability and long-term reliability. By combining state-of-the-art placement systems with advanced soldering technologies, we deliver assemblies that meet the strictest standards — today and in the future.