In-circuit & Functional testing

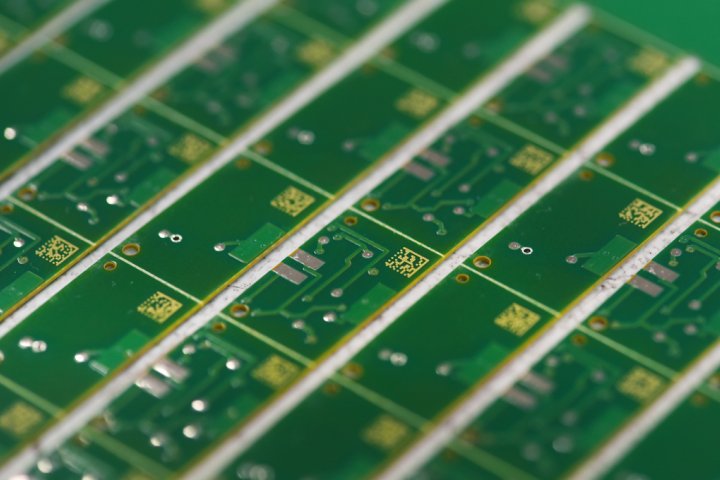

Testing is essential to ensure that electronic assemblies meet the highest standards of functionality, safety, and reliability.

At EPSa, in-circuit and functional testing is integrated directly into the production process, minimizing early failures and reducing the cost of quality assurance.

Advanced testing technology

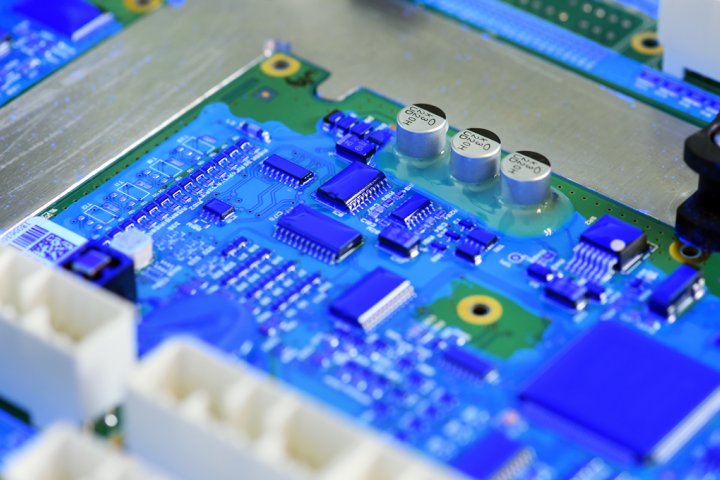

Our test laboratories combine multiple testing methods to guarantee long-term reliability, even in highly sensitive applications such as medical technology, aerospace, and transportation.

Assemblies are tested under realistic conditions, from electrical performance to mechanical stress, with results documented for full traceability.

Testing capabilities include:

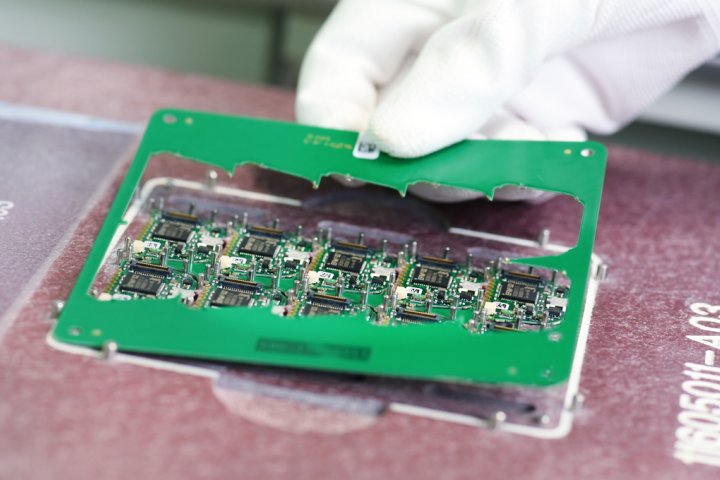

- In-circuit testing (ICT): for electrical verification of components and connections

- Functional testing (FCT): to validate product performance in real operating conditions

- 100% optical inspection (AOI): for solder joints and component placement

- Burn-in and stress testing: under climate conditions for long-term reliability

- High-voltage and isolation testing: to ensure safety compliance

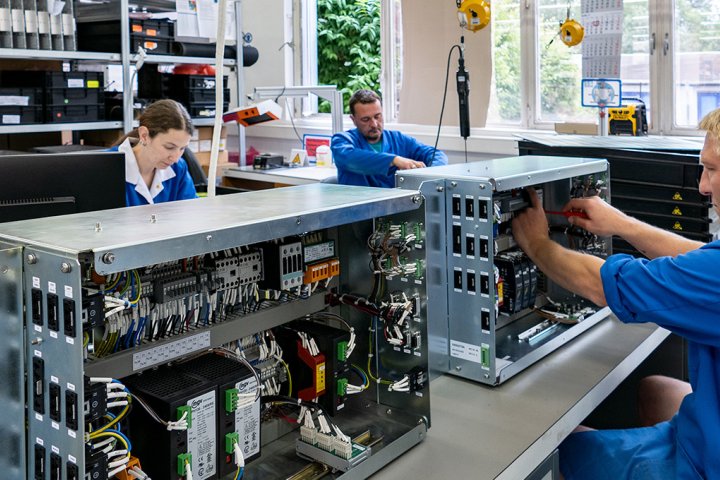

- Cable and back panel testing: for complete system verification

- PC-supported and manual system testing: e.g. telematics applications

- Special mechanical and electronic tests: tailored to customer requirements.

Quality assurance

By integrating in-circuit and functional testing throughout the development and manufacturing process, we ensure that defects are identified early, process monitoring is effective, and product reliability is guaranteed.

Combined with ISO Class 5 clean room testing for sensitive applications, EPSa delivers assemblies ready for the most demanding industries.