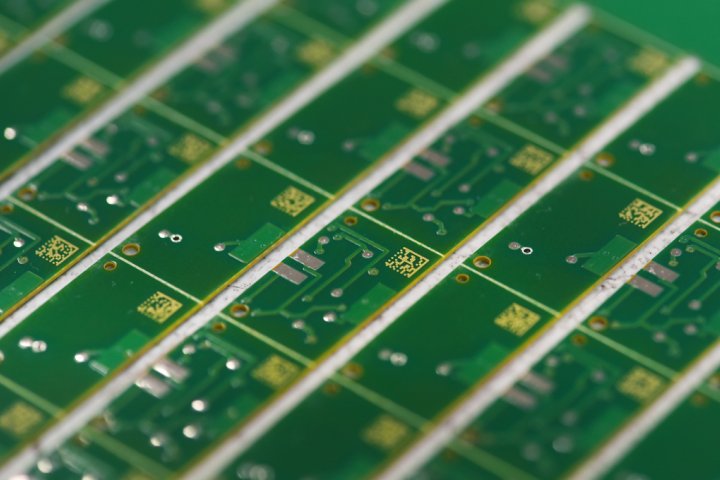

X-ray analyzing & Examining

Some defects are invisible on the surface. That’s why we integrate X-ray analysis at critical stages of the production process to detect hidden errors early and guarantee long-term reliability.

X-ray technology is used during new product introductions to validate soldering processes, and in serial production as part of ongoing AQL checks. This allows us to inspect solder joints under BGAs, void formations, and hidden component connections — areas where traditional optical inspection reaches its limits.

By combining X-ray analysis with other test methods, we create a complete quality assurance process that ensures assemblies meet the highest standards before moving to the next production stage.