Traceability

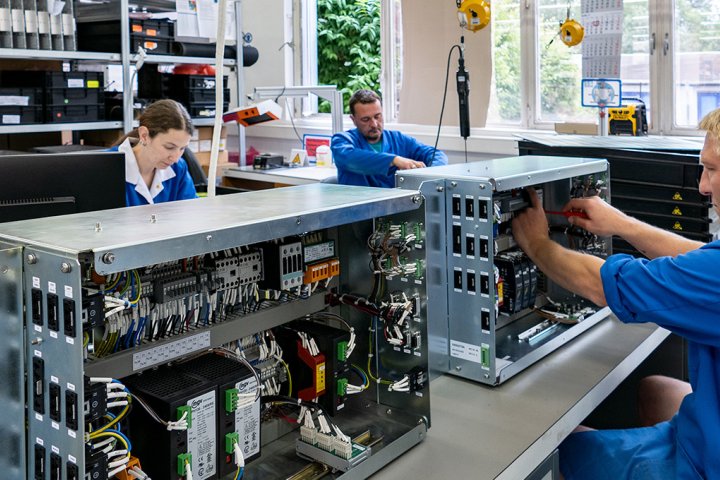

Traceability is an essential part of modern electronics manufacturing. It ensures that every component and every process step can be tracked and documented, from incoming materials to the finished product.

This creates security in redesign projects, supports compliance, and enables rapid response in case of quality issues.

Reliable data management

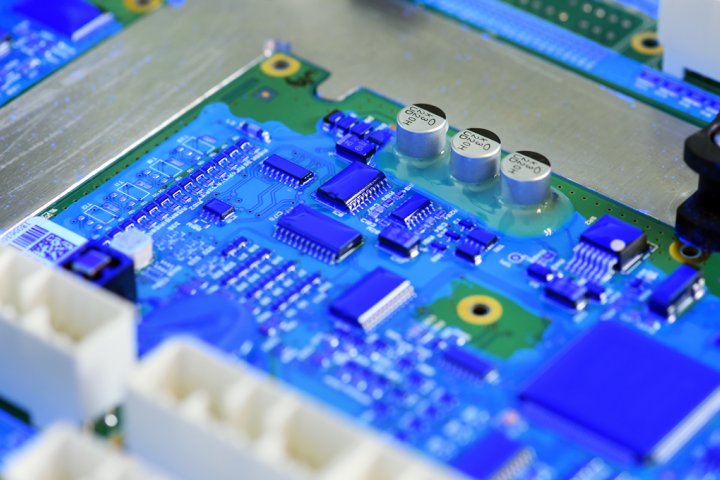

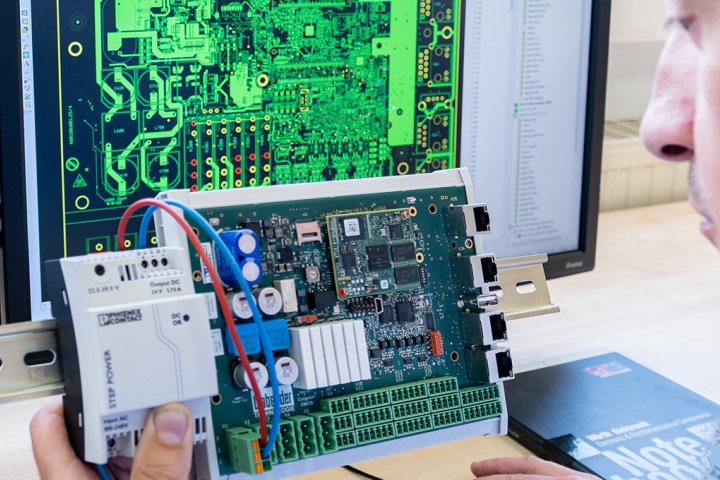

At EPSa, traceability is guaranteed through high-speed labeling and 2D code lasering. Both methods are applied with maximum precision, ensuring that each product is uniquely identifiable. The data behind these codes is captured in detail at both batch and product levels.

All traceability information is recorded in our integrated databases, making it possible to link production, testing, and quality records seamlessly. This allows customers to access full process transparency and documented proof of compliance, not just for critical markets such as Healthcare & Life sciences, but for all industries.

Advanced component tracking

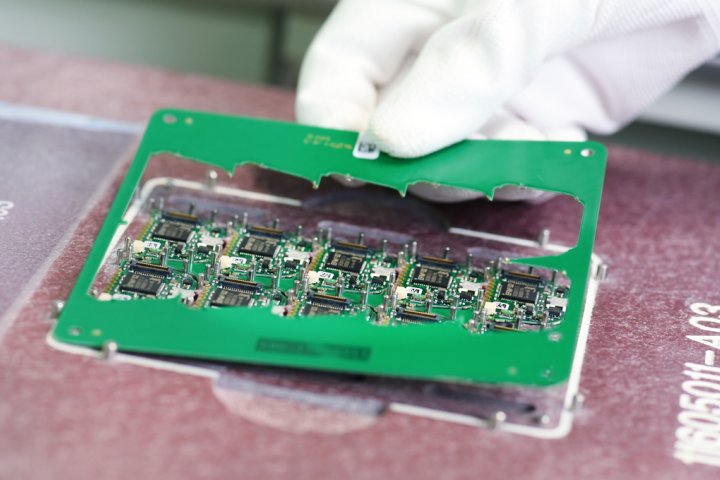

To complement production-level traceability, EPSa also uses the OC-SCAN CCX X-ray component counter. This system counts SMD reels and other packaging forms within seconds, with >99.9% accuracy.

By integrating real-time component counting into our logistics and ERP systems, we ensure precise inventory control, eliminate manual counting errors, and strengthen overall process reliability.