NPI & Prototyping

Introducing a new product is always a critical step. Success depends on more than a good design, it requires clear communication, structured processes, and thorough validation.

With EPSa as your full-service DMS partner, every step of your New Product Introduction (NPI) is carefully managed to ensure speed, reliability, and transparency.

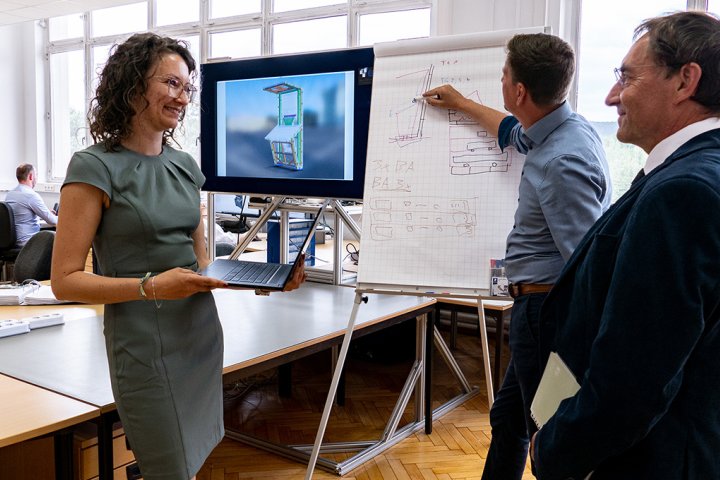

Seamless collaboration

During NPI, you have a single point of contact who coordinates the process end-to-end.

All project data is captured and monitored in our ERP system, ensuring traceability and clear communication at every stage. Together, we analyze results, discuss optimizations, and make informed adjustments, keeping your project on track from day one.

Prototyping as validation

Prototyping is an essential part of NPI.

Each prototype serves as a test run to validate both product design and production process. Results are carefully reviewed with you to identify improvements, reduce risks, and ensure that the design is ready for industrial scale.

Validation includes:

- Temperature profile validation (reflow and wave soldering)

- In-circuit and functional testing

- X-ray and optical inspection

- SPC measurement

- IPC A610 compliance

- Custom prototype testing and reporting.

When speed is critical, our rapid prototyping capabilities provide series-quality samples within days. This shortens development cycles, accelerates validation, and reduces costs — giving you a faster route from idea to industry.

Change management

Optimization always requires adjustments. With our structured change management system, every modification is documented, shared, and approved by all stakeholders before implementation. This guarantees full transparency and ensures a smooth transition from prototype to production.